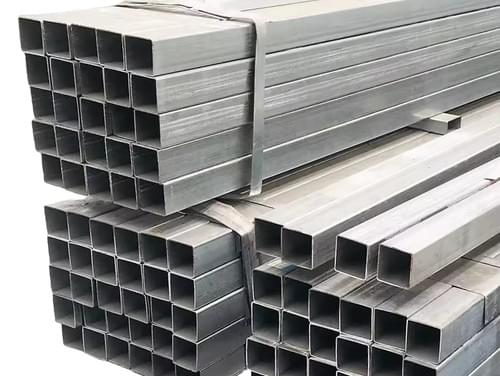

square pipes steel pipes factory

Welded pipe introduction:

Welded steel pipe, also known as welded pipe, is a steel pipe made of steel plate or strip steel after crimping and welding, and the length is generally 6 meters. Welded steel pipe has simple production process, high production efficiency, many varieties and specifications, and less equipment investment, but the general strength is lower than that of seamless steel pipe.

Parameter info:

International standards and parameters

1

American standard square tube: ASTM A500 standard is implemented, with cold forming grading (Gr. A/B/C) for square tubes and an outer diameter tolerance of ± 0.5%

2

European standard square tube: meets EN 10219 cold formed square tube, with a wall thickness range of 1.0-16mm and a diagonal difference of ≤ 1.5mm

3

Japanese standard square tube: Welded square tube according to JIS G3466, commonly used sizes range from 50 × 50mm to 200 × 200mm

4

Australian standard square tube: AS/NZS 1163 square tube, tensile strength ≥ 450MPa, suitable for high corrosion environments

Application scenarios and advantages

1

Building structural square tube:

Efficient bolt connection with square tube right angled edges, saving 30% of steel structure construction time

Square pipes have better bending stiffness than round pipes, and when used as factory columns, the deflection is reduced by 40%

2

Mechanical frame square tube:

The internal space of the square tube facilitates the layout of cables/hydraulic pipes, improving equipment integration

Square tube surface can be milled/drilled, compatible with sensor and actuator installation

3

Transportation square tube:

The car collision beam adopts high-strength square tube (HSLA350 grade), which increases energy absorption by 50%

Fatigue testing of square tubes for rail vehicles (zero cracks after 1 million cycles)

4

Agricultural facility square tube:

Greenhouse square tube skeleton aluminum zinc anti-corrosion (≥ AZ150), with a lifespan of over 15 years

Square tube splicing type grain silo support column, with a wind pressure resistance level of 12

Other steel pipes informationa for reference.

Dimension:

SMLS: Φ10.3~1016×1.7~52mm

WELD: Φ219~2134×5~52mm

Length: Random Length, Fixed Length, SRL, DRL

Steel Grade:

ASTM A53/ASTM A106: GR A, GR B, GR CASME

ASME A500: GR.A, GR.B, GR.C, GR.D

Standard:

API SPEC 5L,ISO 3183,ASTM A 53M,ASTM A 106M,JIS G 3454,JIS G 3455, JIS G 3456

Test Required:

Chemical Analysis, Mechanical Test, Visusal Inspection , Tension Test, Dimension Check, Bend Test , Flattenting Test, Impact Test, DWT Test, NDT Test, Hydrostatic Test, Hardness Test.

Size: OD: 13.72-4064mm / WT: 1.65-40mm,Length: 0.5mtr-20mtr

Standard & Grade : API5L,ASTM A106/A53, DIN2391, ASTM A179/A192, EN10210,EN10208

Ends: Square Ends/Plain Ends (Straight Cut, Saw Cut, Torch Cut), Beveled/Threaded Ends

Usage: For Conveying Gas, Water And Oil Either In The Oil Or Natural Gas Industries

Packing: Bundle Or Bulk , Seaworthy Packing Or For The Client's Requirement

We are a manufacturer that can produce different steel pipes and various steel products. For more product needs, please contact us and we will provide you with a quotation soon. Thank you

Application info:

Carbon steel welded pipe and tube are used in high-pressure conditions. They are highly resistant to shock and vibration, making them ideal to transport fluids. Carbon steel pipes are widely used in a number of industries, such as transporting water and sewage, oil and gas industries, boiler and condenser tubes, high-pressure applications, and chemical processing.

Automobile sectors - Interior & exterior architectural structures - Water pipelines - Gas lines - Oil & Gas industries - Pressure service - Boiler & electric power - Machinery - Gas tank - Chemical engineering - Offshore and petroleum engineering - Transporting water and sewage - Oil and gas industries - Boiler and condenser tubes - High-pressure applications - Chemical processing